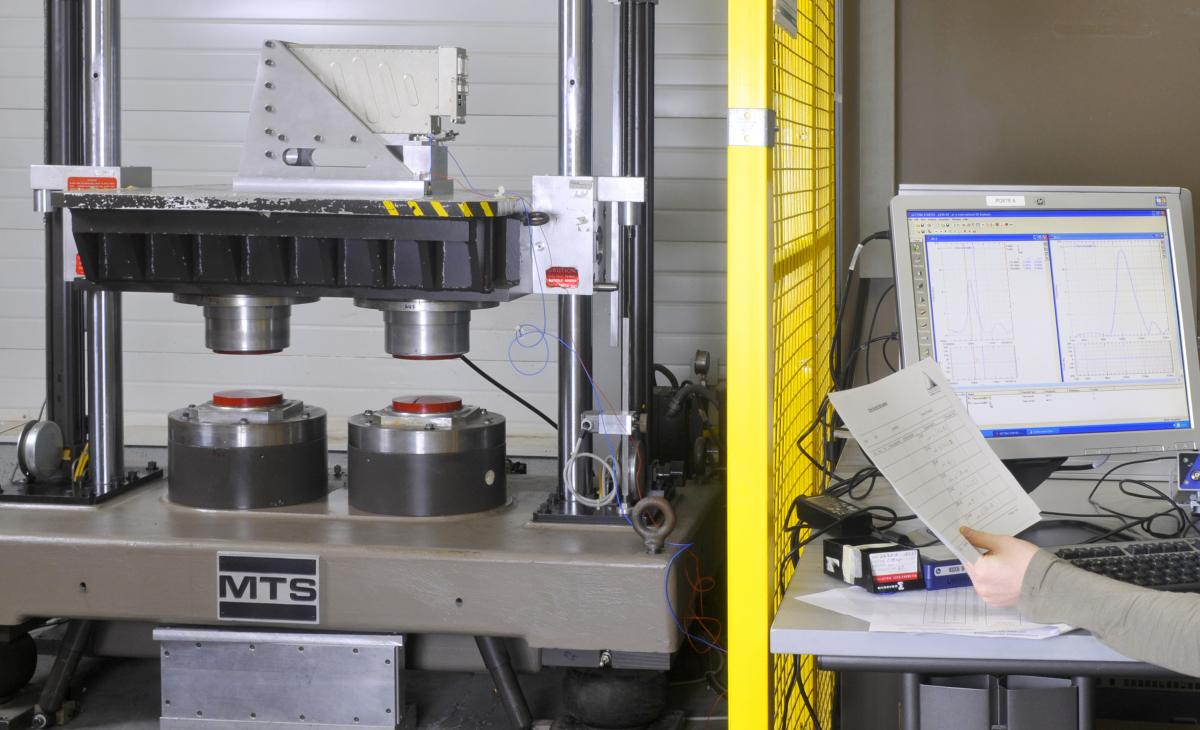

Vibration - Vibration and temperatures tests

Our laboratory is equipped with climatic rooms that can be adjusted on vibration shakers to realise your combined tests.

Expertise

- Harsh environment chamber

- From -60°C to +250°C

- Maximum Volume: 500x500x600

- Controlled temperature chamber

- From -40°C to +150°C

- Volume: 1m3 1x1x1m

Means

- LDS and ETS Electrodynamic shaker

- Frequency range: from 3 to 3000 Hz

- Table size:900 x 900 mm

- Force: 28 000 N, 40 000 N and 60 000 N

- Frequency range: from 3 to 3000 Hz

- Maximum acceleration: 100g

- M+P piloting acquisition chain